When you need the chemical resistance of PTFE—but with better sealability on real-world flanges—expanded PTFE (ePTFE) is often the best choice. ePTFE is widely used in demanding industrial service because it compresses and conforms more easily than standard PTFE, helping reduce leak risk on flanges that have minor surface imperfections, misalignment, or bolt-load limitations.

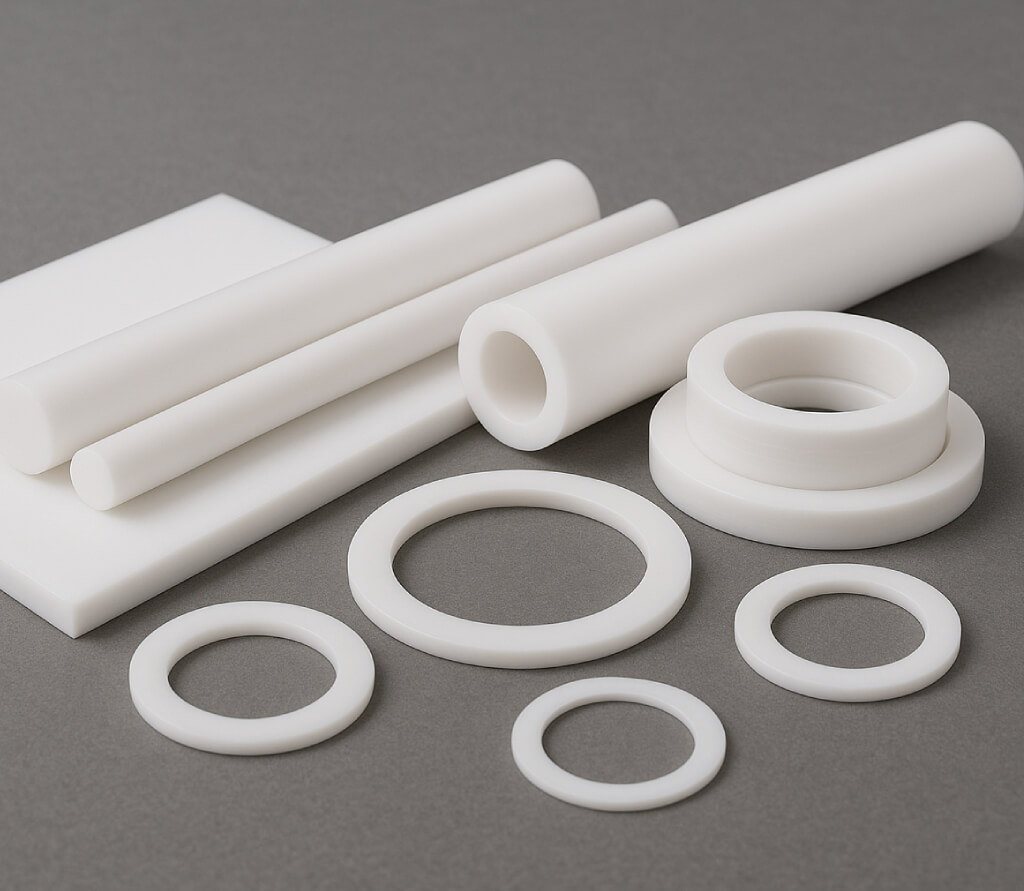

Plastics Fabricating & Machining supplies ePTFE sheet and precision-cut ePTFE gaskets for maintenance, shutdowns, and repeat programs.

Expanded PTFE (ePTFE) is PTFE that has been processed into a micro-porous structure. This structure gives it:

It’s commonly specified in chemical processing, refining, and industrial applications where sealing reliability and chemical compatibility are critical.

Key benefits:

We supply ePTFE gaskets for:

Standard PTFE is more rigid and can be harder to seal on imperfect flanges. ePTFE is more compressible and conformable, often sealing better and reducing leak risk.

Yes—send a PDF/DXF or a physical sample gasket and we can match it.

Yes—full sheets, cut-to-size, and finished gaskets.

Media/chemical, temperature, pressure, flange type, and whether the service cycles hot/cold or sees vibration.

Don't hesitate to contact us!

2945 South Fourth St. Beaumont, Texas 77701

hector@plasticsfm.com